Shot-blasting and paint-spraying section

Spray and drying complex

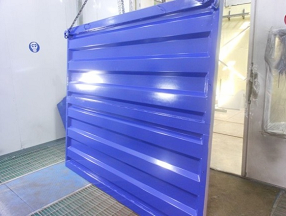

For painting and drying surfaces in different spatial positions a double spray and drying booth is used. Maximum size of goods to be painted is 7000х5000х4000 mm. Any paintwork materials can be applied for painting. Paintwork materials are prepared and stored in a special warehouse with controlled temperature. The warehouse is equipped with ventilation and meets all the requirements of fire protection standards. Two operators can work simultaneously. The coating is given with airless method by the spray installation MERКUR 45:1 (G45C03) of American company GRACO. This installation is driven by a compressor placed on a comfortable 2-wheeled cart that ensures easy and quick removal of equipment when necessary. The installation is equipped with a spray gun XTR 5, a suction hose and a fluid hose 7,5 m. in length.

The following working stages are performed by the spray and drying booth:

STAGE I : WARM UP PAINTING

When painting the temperature inside the booth can be the same as the outside temperature. When warm up painting the temperature can be set.

- STAGE II : BLOWING

Blowing occurs between applying the first and the second layer of paint, or between applying the last layer and the stage of drying. Blowing spreads the paint evenly on the product and removes dust from the booth before the stage of drying.

- STAGE III : DRYING

The temperature inside the booth can be set up to 70ºC with 85% of air in a recirculation mode and 15% of fresh air.

- STAGE IV - COOLING

This stage starts when the set time of drying is over. The cooling time is set using a temperature controller to achieve a minimum temperature of up to 5 ÷ 20 º C.

Painting and drying complex Products after painting

For semi-automatic cleaning of metal products before and after welding a shot-blasting chamber is used.

The chamber has internal dimensions of 7500 х 5460 х 4670 mm (L х W х H. A monorail is installed inside the chamber to supply workpieces weighing up to 2,000 kg.

The overall level of illumination in the chamber’s working area is not less than 1000 lux.

Shot-blasting chamber consists of:

Scraper floor (model SF-7,5-5,4-R)

- Air handling unit with capacity of 20,000 m ³ / h.

- Vacuum system MUNKEBO MB-220 E3

- Blasting machine CLEMCO SCW 2452 SYSTEM 7. Maximum working pressure – 12 bar. Cleaning quality or surface cleanliness after processing Sа3, Sа2 ½, S2.