Blanking section

thickness, mm – up to 25

width, mm – up to 3000

High-accuracy cutting:

Hydraulic shearing machine AMADA GSII-630. High clearance of metal plate cutting into blanks of needed size is achieved by the precision mechanism, positioning the back gauge and the holder to avoid the deflection of a thin (up to 1,5 mm) plate in space. The ruler ensures accurate squareness of cutting blanks. Shearing machine’s capacity allows cutting of a steel plate 3000 mm in length for up to 6 mm thickness and up to 1,2 mm for stainless steel

Cutting of carbon sheet steel

sheet thickness, mm – up to 160

NC thermal cutting equipment ensures cutting of complicated configuration parts made of low-carbon steel

|

Cut thickness range, mm: low-carbon steel (with punching) – 1,5…50(35) stainless steel (with punching) – 1,5…32(20) aluminium (with punching) – 1,5…32(12) |

Bending cylindrical and conical workpieces

max. sheet thickness, mm – 10

min. bending radius, mm – 170

max. bending width, mm – 2000

Bending of pipes, profiles, stripes, angle bars, channel bars, t-beams and j-beams on a specified program.

Min. bending radius, mm – 150

Bending of sheet steel

• Hydraulic press brake AMADA 1703: maximum force 1700кN, bending angle from 88°, eight (Y1,Y2, X1, X2, Z1, Z2, R1, R2) axes with automatic NC. The press-brake is used for bending and forming of geometrically complicated parts from sheet metal.

The press brake allows forming sheets of the following sizes:

• thickness 4-6 mm, width 3m;

• thickness 7 mm, width 2,5

• thickness 8 mm, width 2,0m;

• thickness 10 mm, width 1,5 m;

• thickness 12 mm, width 1m.

Wide variety of optional equipment makes the press brake universal:

• additional axis (Delta-X) of back gauge control for positioning parts when bending at an angle;

• active bending indicators to measure an angle during the bending process;

• sheet holder

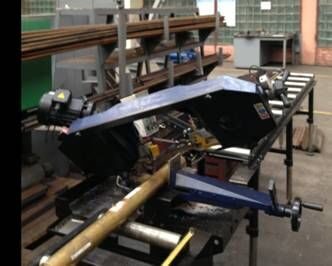

Cutting rounds and structural shapes of various sizes:

rings, pipes, mm – up to 40…250

channel bar, profile, mm – up to 30

cross sectional billet cutting, mm – up to 500

square, mm – up to 500

max. billet length up to stop, mm – up to 1500

For ripping and cross cutting billets from different metals band saw machine Zenitech BS225 is used. It achieves accurate cut with high quality end faces.

|

Maximum size of a workpiece

at 45 degrees, mm 160 (circle) 160 х 160 (square)

at 60 degrees, mm 100 (circle)

at 90 degrees, mm 225 (circle) 245 х 180 (rectangle) |