Removable truck body

Removable truck body is mounted on a vehicle or a container trailer. It is used for transportation of loose goods, including agrarian cultures, and goods on pallets, maximum weight of which does not exceed the acceptable value.

In accordance with traffic laws (p. 22.5) on the territory of Ukraine the movement of vehicles is allowed, actual mass of which does not exceed 44 tons for articulated trucks (container truck) – in comparison with other vehicles max. actual mass is 38 tons.

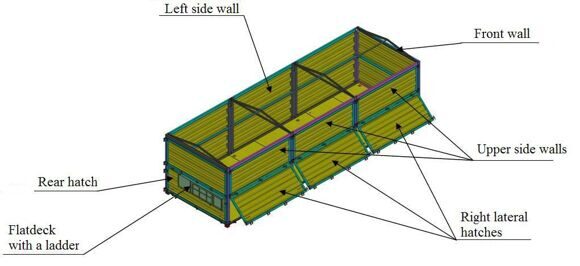

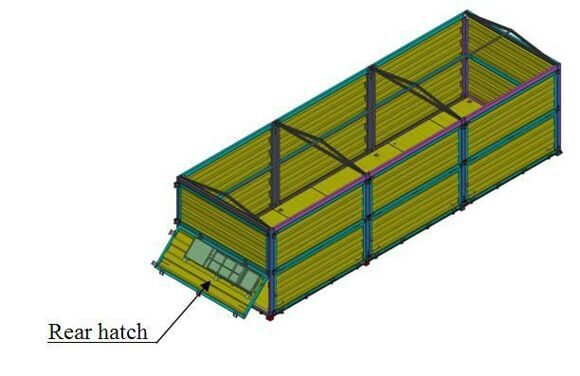

The basic truck body model consists of the following key parts:

- body understructure with lock installation

- front wall

- upper rear wall

- rear hatch

- upper side wall

- lateral hatch

- left side wall

- flatdeck with ladder

- awning frame with a rolling mechanism

Truck body is equipped with awning to protect goods against precipitations.

The body arrangement is dismountable. It makes possible to replace parts.

The bottom is the main part of the truck body. It satisfies the requirements of planarity. The holes in the body bottom ensure its precise fixation to the auxiliary frame for BDF system. The distance between the holes for locks (fittings) makes 5853мм, similarly to a 20-foot container.

Body bottom is a welded construction consisting of roll-formed sheet profile and flats. The lower part of the body bottom contains latching mechanisms which fix hatches in vertical position and prevent loose goods from emptying.

A handle of a latching mechanism and a lever mechanism are made with fixation in extreme closed position. Besides, additional fixation of extreme closed position is ensured by a spring loaded lever arm. All body assemblies are fastened to the body bottom with the help of bolting that makes it easier to repair.

Bolting has fine pitch thread to avoid twisting off.

Left side wall is all-welded.

Right side wall consists of three upper side walls and three lateral hatches.

Upper side walls are fastened to pillars by rolling vertical loops. Lateral hatches are fastened to the lower part of upper side walls with the help of horizontal loops. Vertical loops ensure opening of upper side walls and hatches in the vertical plane at 90° relative to lateral body surface. Horizontal loops make it possible to open hatches at 90° relative to horizontal body surface. Lateral hatches are designed for emptying of loose goods through lower part of side wall. With the simultaneous opening of upper side walls and bottom hatches in a vertical plane loading and unloading of cargo on pallets is performed.

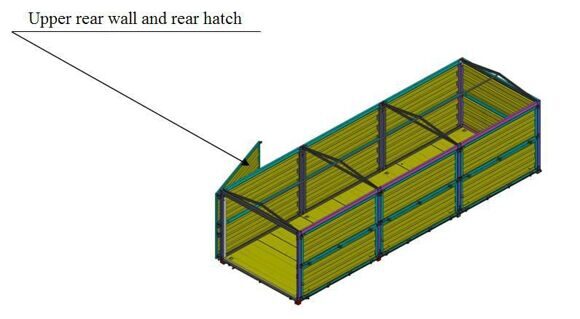

Rear end of the body consists of an upper rear wall and a rear hatch. These wall and hatch are functioning in a similar manner as walls and hatches of the right side of the body but they have possibility to be opened in the vertical plane at 270°.

Rolling loop has a wear-resisting washer in its lower loop bearing surface. It prevents loops from wear and tear. When a washer is worn out it is replaced by a new one.

An example of body identification

An example of identification of the body (type KA40, model 3) for dropping on the chassis of a truck (N3-category, 40 m³) when concluding a contract: «Removable truck body KA40-1 ТУ У 29.2-30793280-006:2014». Table 1 contains a list of body types with the corresponding body space.

Table 1.

| Body type |

Fully loaded mass,kg - 50kg |

Length, mm, - 15mm. |

Width,mm - 10mm. |

Height mm, - 10mm. |

Body space, m3, - 0,5 m3 |

|

| Truck | Trailer | |||||

| КА29 | КР29 | 1950 | 6700 | 2550 | 2050 | 29 |

| КР34 | 2270 | 6700 | 2550 | 2240 | 34 | |

| КА34 | 2270 | 6700 | 2550 | 2330 | 34 | |

| КА31 | КР31 | 2070 | 7100 | 2550 | 2050 | 31 |

| КР36 | 2400 | 7100 | 2550 | 2240 | 36 | |

| КА36 | 2400 | 7100 | 2550 | 2330 | 36 | |

| КР38 | 2550 | 7450 | 2550 | 2240 | 38 | |

| КА32 | КР32 | 2300 | 7450 | 2550 | 2050 | 32 |

| КА38 | 2550 | 7450 | 2550 | 2330 | 38 | |

| КР40 | 2670 | 7820 | 2550 | 2240 | 40 | |

| КА40 | 2670 | 7820 | 2550 | 2330 | 40 | |

| КР40,5 | 2700 | 7900 | 2550 | 2240 | 40,5 | |

List of models and their functional use you can see in section «Models»

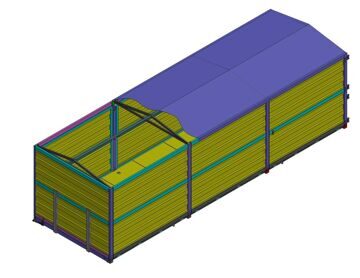

At Pic.1 you can see a removable body when closed

Pic.1

Inside the body between the pillars there are tension chains which fix the distance between the body sides and serve to improve the characteristics of strength.

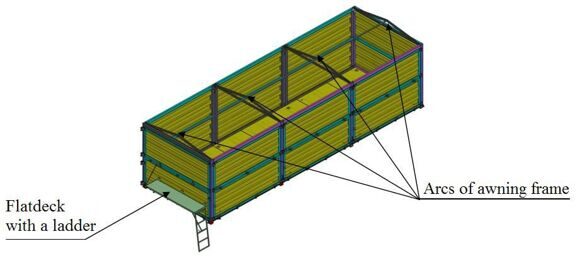

Upper part of the body is covered with the awning rolling to the left side wall with the help of a removable handle. It’s also possible to shift the arcs of awning frame at 90°, which makes it possible to drive into a low hangar.

To make the process of awning rolling easier there is a flatdeck with a ladder (see Pic. 3). From the inner and outer side of upper rear wall rungs are welded for a driver to get into the body.

Pic.2

While driving the flatdeck with a ladder is folded and fastened on the rear hatch (see Pic.3). The base model body design allows of opening of right and rare side walls. Left side wall is all-welded in this version.

Functionality of the base model body.

There are two variants of loading and unloading from the right side:

1) when right lateral hatches are opened– for loose goods (see Pic.3)

Pic.3

2) when upper side walls and hatches are opened together – for goods on pallets (see Pic. 4)

Pic.4

There are three variants of loading and unloading from the rear of the body:

1) when the upper wall and the rear hatch are opened at 270° for goods on pallets (see Pic. 5)

2) when the rear hatch is opened for emptying of loose goods (see Pic. 6)

3) when the upper rear wall is opened for loading of loose goods (see Pic. 7)

Layout of cargoon 1200х800mm pallets:

1. Disposition of cargo on pallets in 7820mm body when loading from the right. Number of pallets in one line is 18 (see Drawing 1).

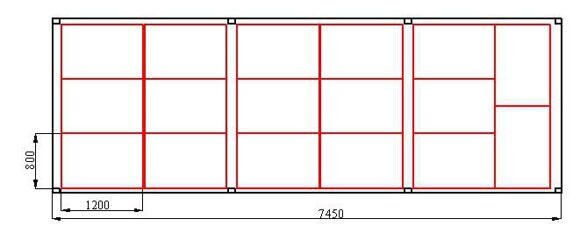

2. Disposition of cargo on pallets in 7450mm body when loading from the right. Number of pallets in one line is 17 (see Drawing 2).

Drawing 2

3. Disposition of cargo on pallets in 7820mm body, rear loading. Number of pallets in one line is 18 (see Drawing 3).

4. Disposition of cargo on pallets in 7450mm body, rear loading. Number of pallets in one line is 18 (see Drawing 4).

Dropping of the body on a chassis is performed when empty. Removable body design makes it easier to repair and maintain the truck.